Our lab is equipped with a diverse suite of state-of-the-art instruments that support advanced research in food, agriculture, and biosensing. These instruments enable non-destructive, rapid, and high-throughput analysis of chemical and physical properties of various biological materials.

Rapid Composition Analyzers (Full description below)

SMART 6: Moisture and solids analysis in less than 5 minutes.

Oracle: Rapid, solvent-free fat analysis.

Sprint: Protein analysis system using nitrogen-free technology.

In-House Developed Systems (Full description below)

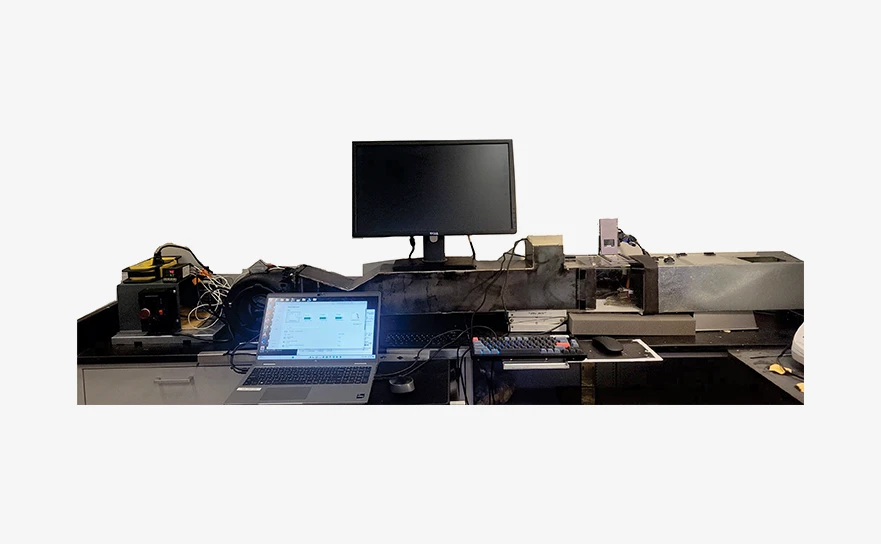

Smart dryer: Lab-designed drying system with real-time monitoring capability for drying kinetics and process optimization.

Electronic nose (E-nose): Custom-designed system for volatile compound detection and aroma profiling.

These instruments collectively support a broad range of applications including quality assessment, authentication, adulteration detection, and real-time process monitoring.

RGB FUSION NOSE

- Description

- Functionality and Features

- Sensors and Their Target Gases

- Use

The eNose is an electronic nose system equipped with eight Metal Oxide Semiconductor (MOS) gas sensors. Each sensor is specialized in detecting specific gases, making the eNose capable of identifying and differentiating a wide range of volatile organic compounds (VOCs) and gases. This versatile sensor array is commonly used for environmental monitoring, industrial applications, and research purposes. This equipment combines the power of an RGB sensor with MOS gas sensors to provide comprehensive detection and analysis capabilities.

- Multi-Gas Detection: Equipped with eight different MOS sensors, each targeting specific gases, enabling the detection and differentiation of a wide range of VOCs and gases.

- High Sensitivity: Provides high sensitivity to low concentrations of gases, allowing for accurate detection and analysis.

- Compact and Portable Design: The eNose system is designed to be compact and portable, making it suitable for field use and on-site analysis.

- Real-Time Analysis: Capable of real-time monitoring and analysis, providing immediate results for quick decision-making.

- Easy Integration: Can be easily integrated into existing systems and platforms for data collection and analysis.

- Data Logging: Features data logging capabilities, allowing for the recording and storage of measurement data for further analysis.

- RGB Camera: Equipped with a Raspberry Pi Sony RGB camera, enhancing its capability to capture and analyze visual data in conjunction with gas detection.

- MQ-2: Detects LPG, i-butane, propane, methane, alcohol, hydrogen, and smoke.

- MQ-3: Sensitive to alcohol, benzine, CH4, hexane, LPG, CO.

- MQ-4: Primarily detects methane (CH4) and other natural gases.

- MQ-5: Sensitive to LPG, natural gas, town gas, and CH4.

- MQ-6: Detects LPG, butane, propane, methane, and alcohol.

- MQ-8: Sensitive to hydrogen (H2) gas.

- MQ-135: Detects a variety of harmful gases including ammonia (NH3), nitrogen oxides (NOx), alcohol, benzene, smoke, and CO2.

- MQ-138: Sensitive to toluene, acetone, ethanol, CO, NH3, H2S.

- Environmental Monitoring: Utilized for detecting and monitoring air quality, pollutants, and hazardous gases in the environment, with the RGB sensor aiding in visual data collection.

- Industrial Applications: Employed in industries for leak detection, safety monitoring, and quality control, where the RGB sensor can provide visual confirmation and support.

- Food and Beverage: Used for monitoring freshness, spoilage, and quality control in food products, with the RGB sensor assisting in identifying visual changes indicative of quality.

- Healthcare: Assists in medical diagnostics by detecting specific biomarkers in breath analysis, where the RGB sensor can be used for visual assessment and confirmation.

- Research and Development: Facilitates research in various fields by providing accurate gas detection and analysis, with the RGB sensor enhancing data collection through visual monitoring.

Smart Convective Dryer

- Description

- Functionality and Features

- Use

The smart convective dryer is an advanced drying system equipped with capabilities for precise temperature control and airflow management. It reaches temperatures up to 70°C and airflow velocities up to 5 m/s, optimizing drying efficiency and uniformity. Additionally, it is integrated with Near-Infrared (NIR), RGB (Red, Green, Blue), and Hyperspectral Imaging (HSI) systems to enhance its functionality for comprehensive analysis during the drying process.

- Temperature Control: Offers precise temperature control up to 70°C, ensuring optimal drying conditions for various materials and products.

- Airflow Velocity: Capable of airflow velocities up to 5 m/s, facilitating rapid and uniform drying.

- Convective Drying: Utilizes convective heat transfer principles to efficiently remove moisture from samples.

- Integrated Sensors:

- Near-Infrared (NIR): Provides real-time moisture content analysis during drying, offering insights into drying kinetics and quality assessment.

- RGB Imaging: Enables visual monitoring and assessment of product color changes and uniformity during the drying process.

- Hyperspectral Imaging (HSI): Allows detailed analysis of chemical composition and quality attributes of dried products across a wide spectral range.

- Food Industry: Used for drying fruits, vegetables, herbs, and spices while monitoring moisture content and color changes with NIR and RGB systems.

- Pharmaceuticals: Facilitates drying of pharmaceutical ingredients and products with precise control over drying parameters and quality assessment using HSI and NIR technologies.

- Chemical and Material Sciences: Supports drying of chemicals, polymers, and other materials while analyzing composition changes and uniformity with HSI and NIR imaging.

- Research and Development: Utilized in R&D labs for studying drying kinetics, optimizing drying protocols, and developing new drying processes based on comprehensive analysis from integrated imaging systems.

SPRINT RAPID PROTEIN ANALYZER

- Description

- Functionality and Features

- Use

The Sprint Rapid Protein Analyzer from CEM Corporation is an advanced instrument designed for the quick and accurate determination of protein content in various samples. It utilizes a unique dye-binding method to provide precise results without the need for hazardous chemicals.

- Dye-Binding Method: Uses a proprietary dye-binding technique to measure protein content accurately and reliably, eliminating the need for traditional methods involving hazardous chemicals.

- Rapid Analysis: Delivers results in just a few minutes, significantly faster than traditional Kjeldahl or combustion methods.

- High Precision and Accuracy: Ensures repeatable and reliable protein content measurements, suitable for quality control and compliance with industry standards.

- User-Friendly Interface: Features an intuitive touchscreen interface with simple operation and minimal training requirements.

- Environmentally Friendly: Does not require hazardous chemicals or reagents, making it safer for the operator and the environment.

- Versatility: Capable of analyzing a wide range of sample types, including food products, animal feed, and agricultural samples.

- Compact Design: Occupies minimal bench space, making it suitable for laboratories with limited space.

- Food Industry: Used for determining protein content in various food products, such as meat, dairy, and processed foods, supporting quality control and nutritional labeling.

- Animal Feed: Assists in analyzing protein content in animal feed, ensuring proper nutritional balance and quality.

- Agriculture: Supports protein analysis in agricultural products, aiding in quality assessment and crop management.

- Research and Development: Facilitates protein content measurement in research and development projects, aiding in product formulation and quality assessment.

SMART 6 Moisture and Solids Analyzer

- Description

- Functionality and Features

- Use

The SMART 6 Moisture and Solids Analyzer from CEM Corporation is an advanced instrument designed for rapid and precise measurement of moisture and solids content in various samples. Utilizing a combination of microwave and infrared drying technologies, the SMART 6 delivers accurate results quickly and efficiently.

- Dual Technology: Combines microwave and infrared drying technologies to provide fast and accurate moisture and solids analysis.

- Rapid Analysis: Delivers results in minutes, significantly reducing the time compared to traditional drying methods.

- Versatility: Capable of analyzing a wide range of sample types, including food products, chemicals, pharmaceuticals, and more.

- User-Friendly Interface: Features an intuitive touchscreen interface and easy-to-follow prompts, minimizing the need for extensive operator training.

- High Precision and Accuracy: Provides reliable and repeatable results, suitable for quality control and regulatory compliance.

- Non-Destructive Testing: Allows for further analysis of the sample if needed, as the measurement process does not alter the sample significantly.

- Compact and Efficient Design: Designed to occupy minimal bench space while delivering maximum performance.

- Food Industry: Used for moisture and solids content analysis in various food products, supporting quality control and ensuring product consistency.

- Pharmaceuticals: Assists in determining moisture content in pharmaceutical products, crucial for stability and efficacy.

- Chemical Industry: Utilized for moisture analysis in chemicals and raw materials, ensuring compliance with industry standards.

- Agriculture and Feed: Supports moisture and solids analysis in agricultural products and animal feed, aiding in quality assessment and nutritional evaluation.

- Environmental Testing: Employed in environmental laboratories for analyzing moisture content in soil and other samples.

ORACLE RAPID NMR FAT ANALYZER

- Description

- Functionality and Features

- Use

The Oracle Rapid NMR Fat Analyzer is an advanced nuclear magnetic resonance (NMR) instrument designed for quick and precise fat content analysis in various samples. This state-of-the-art analyzer provides a non-destructive, solvent-free method for determining fat content.

- Precision and Accuracy: Provides highly accurate and repeatable fat content measurements, suitable for quality control and compliance with industry standards.

- Rapid Analysis: Capable of delivering results in minutes, significantly faster than traditional methods such as Soxhlet extraction.

- Non-Destructive Testing: The NMR technique does not alter the sample, allowing for further analysis if needed.

- Solvent-Free: Eliminates the need for hazardous solvents, making the analysis safer and more environmentally friendly.

- Ease of Use: Features an intuitive user interface and automated operation, minimizing the need for extensive operator training.

- Versatility: Can analyze a wide range of sample types, including food products, animal feed, and cosmetics.

- Compliance: Meets regulatory requirements and industry standards for fat content analysis, ensuring reliable and accepted results.

- Food Industry: Used for determining fat content in dairy products, meats, oils, and processed foods, supporting quality control and product labeling.

- Animal Feed: Assists in the analysis of fat content in animal feed, ensuring proper nutritional balance and quality.

- Cosmetic Industry: Utilized for analyzing fat content in cosmetic products, ensuring consistency and quality.

- Research and Development: Supports R&D activities by providing precise fat content measurements, aiding in product formulation and quality assessment.